Shanghai Link-Point Information Technology Co., Ltd. will make a strong appearance at this exhibition, presenting its latest RFID intelligent production equipment and digital printing solutions. The company will demonstrate its full-process capabilities covering RFID high-speed encoding, digital printing, AI visual inspection, and intelligent packaging, offering visitors an in-depth look at advanced smart manufacturing technologies.

Exhibitor Introduction

Shanghai Link-Point Information Technology Co, Ltd.

Booth number: 9C38

August 26-28, 2026

Shenzhen World Convention and Exhibition Center

Company Profile

Shanghai Link-Point Information Technology Co., Ltd. is a national high-tech enterprise specializing in the R&D and system integration of IoT RFID intelligent production equipment, intelligent packaging, and traceability systems. The company provides end-to-end solutions ranging from RFID high-speed encoding and UV digital printing to visual quality inspection and intelligent packaging, enabling customers to build efficient, automated, and traceable production lines.

With a seasoned in-house hardware and software R&D team, Link-Point is capable of delivering customized equipment and system solutions tailored to specific production processes. Its solutions are widely applied across industries including apparel, pharmaceuticals, logistics, and more, enabling seamless integration with Industry 4.0 and MES systems.

Certified under ISO 9001, Link-Point holds multiple software copyrights and has received several IOTE Gold Awards. Upholding the philosophy of “Integrity, Enterprise, and Innovation”, the company is committed to delivering efficient, stable, and one-stop intelligent production services.

Video Preview | Link-Point Smart RFID Production Solutions

▶ Watch the video preview: https://eng.iotexpo.com.cn/v/liandian.mp4

Core Business

Link-Point focuses on the research, development, and manufacturing of RFID high-speed encoding systems, color digital printing and laser marking equipment, AI visual inspection devices, and intelligent machinery, alongside the development of supporting software platforms.

By integrating hardware and software innovation, the company provides traceability solutions supporting ESG-driven circular economy initiatives and carbon footprint management. Its independently developed equipment is extensively used in the production, traceability, and marketing of electronic anti-counterfeiting labels, smart cards, and hang tags, serving industries such as apparel, footwear & headwear, food & pharmaceuticals, medical devices, agriculture, electronics, aviation, logistics & warehousing, daily chemicals, publishing, asset management, and automotive.

Featured Products at the Exhibition

Tag Encoding, Digital Printing, AI Quality Inspection, Scrapping, Counting and Sorting Machine

Known as “the easy-to-operate expert in high-speed RFID card printing”, the RFID-801C integrates encoding, digital printing, AI inspection, defective rejection, counting, and stacking into one compact system.

The machine supports various label sizes and materials, including PE, PET, HDPE, and PVC. Powered by Link-Point’s proprietary PL-800 software, it enables high-speed variable data printing of text, numbers, barcodes, QR codes, and graphics, reaching speeds of up to 90 meters per minute at 600 DPI.

The AI inspection module automatically rejects defective products and compensates quantities, while production data can be seamlessly connected to MES systems, enabling automated, efficient, and intelligent tag production.

Reel Label Coding, Single-Color Digital Printing, AI Quality Inspection, and Defective Marking Machine

The RFID-608C is praised as an “all-round web-fed pro” for RFID encoding and printing. It combines RFID encoding, UV digital printing, and AI inspection in one integrated solution, achieving production speeds of up to 30 pieces per second.

Compatible with paper, plastic, and PVC/PP/PE films, the system supports defective product marking and automatic quantity replenishment. Its main drive and tension systems are controlled by three servo motors, ensuring stable and precise operation. Optional edge correction further enhances reliability, making it ideal for high-mix, low-volume production.

Reel Label Coding, Color Digital Printing, AI Quality Inspection, and Defective Marking Machine

The RFID-610 is a “versatile all-rounder for intelligent roll label production”, integrating high-speed RFID encoding, full-color digital printing, AI visual inspection, and defective marking into a single platform.

Capable of processing labels as narrow as 10 mm, the machine features a high-precision tension and positioning system to ensure accurate color registration. Its advanced color management system supports RIP processing speeds of up to 20 sheets per second, enabling real-time, high-speed printing. The system is fully compatible with MES integration and modular customization.

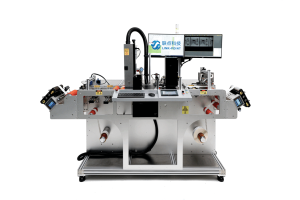

Reel Label Double-Side Digital Printing, AI Quality Inspection, and Defective Marking Machine

The LD-618S fully lives up to its reputation as a “positioning master for duplex roll material printing”. It integrates double-sided digital printing and AI quality inspection, achieving printing speeds of up to 50 meters per minute.

Equipped with imported Japanese sensors, the system delivers a registration accuracy of ±0.01 mm, while its magnetic powder tension control system ensures precise tension regulation and consistent print quality. It is designed to meet the demands of high-end, double-sided label production.

Visit Link-Point at Booth 9C38

At this exhibition, Shanghai Link-Point Information Technology Co., Ltd. will comprehensively demonstrate its innovations in RFID intelligent manufacturing and digital printing. Visitors are warmly invited to Booth 9C38 to explore collaboration opportunities and discover new possibilities for smart production and digital transformation.