Shenzhen Wing Singa Automatic Equipment Co., Ltd will showcase its latest automated solutions for garment label processing and RFID inspection at this exhibition. The company will present a comprehensive range of equipment covering garment label cutting and folding, RFID tag inspection and encoding, as well as AI visual quality inspection, offering visitors a closer look at efficient, intelligent, and reliable label automation technologies.

Exhibitor Introduction

Shenzhen Wing Singa Automatic Equipment Co., Ltd

Booth number: 9D68

Website: http://www.wslabel.cn/en/

August 26-28, 2026

Shenzhen World Convention and Exhibition Center

Company Profile

Shenzhen Wing Singa Automatic Equipment Co., Ltd is a professional manufacturer and supplier of automated equipment, specializing in garment label cutting and folding machines, RFID tag inspection and encoding solutions, and AI visual inspection equipment for label quality control.

With a strong focus on R&D in these three core areas, the company is dedicated to delivering stable, highly efficient, and user-friendly equipment solutions for global clients. Its products have gained wide recognition across China, Europe, America, Southeast Asia, Japan, South Korea, and other regions.

Upholding the business philosophy of customer-centricity, quality first, and innovation leadership, Wing Singa continues to provide professional and high-quality services, earning long-term trust and recognition from customers worldwide.

▶ Watch the video preview: https://www.youtube.com/watch?v=F7U-gZ5qTJ4

View the company brochure: https://s1.iotexpo.com.cn/IOTE/CoFile/SZ202508/771B9B28F5F24020.pdf

Core Business

Wing Singa focuses on the production, sales, and development of automated equipment and system solutions for the garment label and RFID industry, including:

- Production and sales of garment label cutting and folding machines

- Production and sales of RFID tag inspection and encoding devices

- Production and sales of AI visual quality inspection equipment for garment labels

- Development of RFID reading and encoding systems

- Sales of machine parts

Through continuous innovation and quality-driven manufacturing, the company supports garment manufacturers and label converters in achieving higher efficiency, improved quality control, and intelligent production upgrades.

Featured Products at the Exhibition

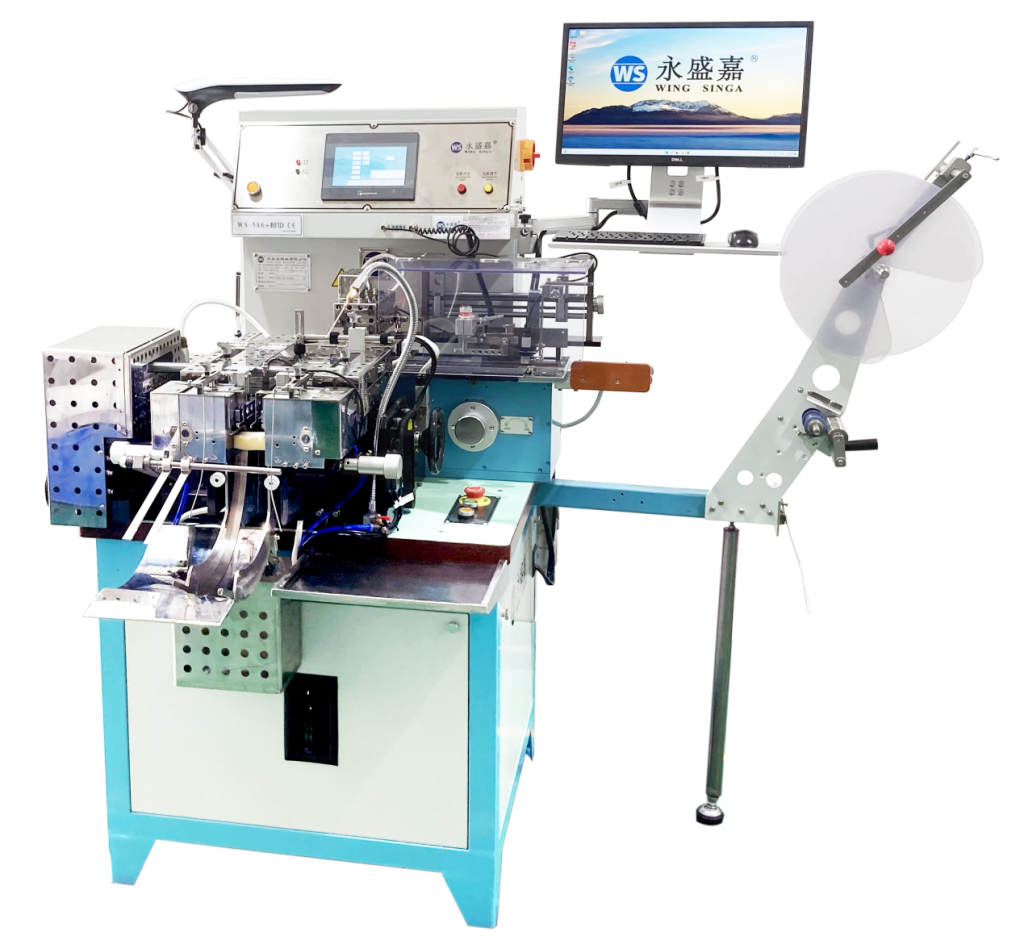

The WS-586+RFID is capable of cutting and folding RFID woven labels and printed labels while performing EPC inspection and encoding. The system automatically rejects EPC-defective products, ensuring reliable RFID performance and stable production output.

Applications:

This machine is widely applied in the inspection and processing of garment RFID woven labels and printed labels.

The WS-368+RFID is designed for detection, inspection, and encoding of garment RFID printed labels. Equipped with an ultrasonic slicing function, it supports various common printed label materials and automatically rejects labels that fail post-encoding verification.

Applications:

It is applied to the detection and encoding of garment RFID printed labels.

The WS-S680 is designed for inlay labeling and inspection of roll-fed garment RFID labels, especially woven labels. Its core functions include inlay labeling, optional post-labeling alignment inspection, optional RFID data reading and verification, and optional defective product marking.

Applications:

It is applied to the labeling and processing of garment RFID woven labels and printed labels.

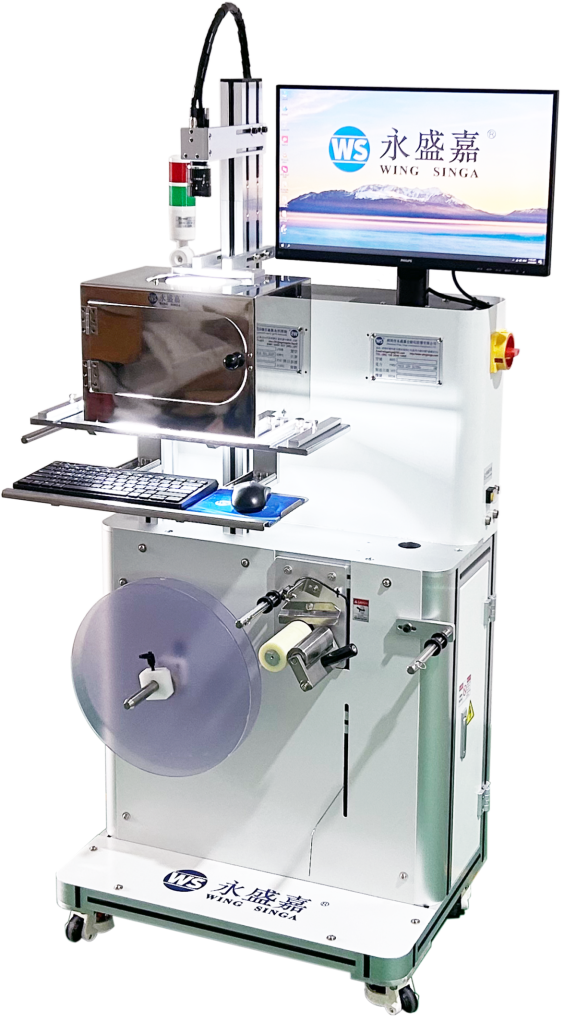

The WS-S580 is designed for surface quality inspection of garment woven and printed labels. Utilizing industrial cameras and AI inspection software, it detects defects such as flaws, stains, thread skipping, missing characters, incorrect patterns, deformation, or gaps, and automatically rejects defective products.

Applications:

It is applied to the quality inspection and processing of garment woven labels and printed labels.

Visit Link-Point at IOTE EXPO 2026

At this exhibition, Shenzhen Wing Singa Automatic Equipment Co., Ltd will comprehensively demonstrate its automated garment label processing and RFID inspection solutions. Visitors are warmly invited to the Wing Singa booth to explore advanced equipment, discuss cooperation opportunities, and discover new possibilities for intelligent label production.