At the recent AIPIA & AWA Smart Packaging World Conference in Amsterdam, Chloe So, co-founder and CEO of PulpaTronics, delivered a striking speech that revealed the importance of traditional RFID technology in inventory management, while also pointing out the huge waste and environmental pollution problems hidden behind the technology. According to So, more than 40 billion RFID tags are landfilled or recycled every year after a short lifespan, but the materials of these tags are not effectively recycled, which not only causes a huge waste of resources, but also exacerbates environmental pollution.

In response to this situation, PulpaTronics has proposed an innovative solution - a completely chip-free and metal-free paper smart label. This technology is not only an innovation of traditional RFID technology, but also an in-depth practice of the concept of sustainable development.

Compared with traditional metal RFID tags, PulpaTronics' paper smart labels reduce carbon dioxide emissions by 70% during the manufacturing process and reduce costs by half. The key to this technological breakthrough is to use laser technology to directly sense the conductive circuit from the substrate, converting the carbon component in the paper into a conductive carbon-based material that is closer to graphite or graphene. In this way, PulpaTronics simplifies the entire manufacturing process and the final product is just a piece of paper, which is both environmentally friendly and economical.

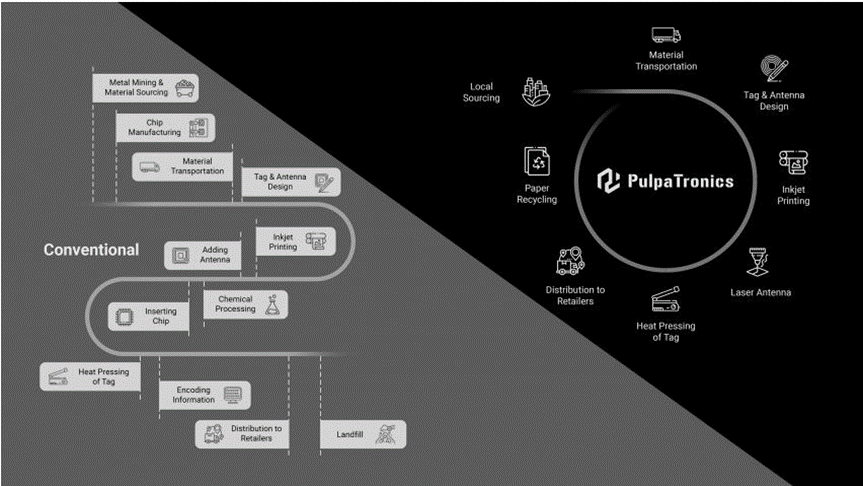

Compared with standard RFID, it takes fewer steps to make Pulpatronics tags

It is worth mentioning that PulpaTronics' paper smart labels not only have the functionality of traditional RFID tags, such as supply chain tracking, inventory counting and anti-theft, but also have higher cost-effectiveness. So revealed in his speech that the cost profit margin of these tags has increased by 8% to 37% over the industry standard. In addition, the tags can be recycled through existing systems, providing strong support for achieving a more circular economy.

PulpaTronics' R&D focus is mainly on two areas: substrates and laser etching. At present, the company is focusing on the research and application of paper materials, but has determined that the technology has the potential to be extended to other plant materials such as cotton, coconut shells or banana peels. This prospect not only opens up a new direction for the development of RFID technology, but also injects new vitality into the cause of sustainable development.

Looking to the future, PulpaTronics has a clear market positioning and development plan. The company plans to launch its hybrid products in the UK market first and gradually expand to other regions. The markets it focuses on include healthcare, clothing and FMCG/CpG, where the demand for RFID technology is large and growing.

In terms of specific marketing plans, PulpaTronics has developed a detailed 18-month development plan. Careful arrangements have been made for each link, from finalizing product specifications to internal production, piloting with retail and packaging partners, designing large production lines, and working with suppliers. So said that PulpaTronics will first bring its hybrid products to the market, which can be seamlessly integrated into the existing infrastructure and operate in the same way, while providing greater cost-effectiveness and sustainability.

Finally, So emphasized the mission and vision of PulpaTronics: "We are the ones who really strive to promote sustainable development, and we really believe that our products can help you achieve your sustainable development goals. Therefore, we want to make sure we understand the impact of this situation, what your company's goals are, and how we can help you achieve these numbers and package them with a beautiful story. We hope to help companies save more money, improve the level of commodity tracking across more industries, and protect more global resources."

PulpaTronics' paper smart labels have undoubtedly injected new vitality into the development of RFID technology and provided new possibilities for sustainable development. This innovative technology is expected to lead the RFID industry to a more environmentally friendly, economical and sustainable future.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)