In 1959, American physicist Richard Feynman, in his famous speech "There's Plenty of Room at the Bottom", proposed the idea of miniaturizing machines to the atomic and molecular scale. However, it was not until the 1980s and 1990s that MEMS technology began to be developed and commercialized.

In 1962, the first silicon micro pressure sensor, a pioneer of tiny devices, was introduced, which pioneered MEMS technology and was also the starting point of MEMS micro sensors. Related papers from Honeywell Research Center and Bayer Laboratory show that they invented the first silicon diaphragm pressure sensor and strain gauge.

Since then, people's interest in MEMS sensor technology has increased dramatically, and by the late 1960s, many pioneering American companies had begun to produce the first MEMS pressure sensors.

Richard Feynman

MEMS technology is developing rapidly and plays a key role in the popularization of today's sensors. Without MEMS technology, it will be difficult to achieve miniaturization, integration, and low power consumption of sensors, and the development of the Internet of Things, smart phones, and automobiles will also lag seriously behind.

MEMS microphones: popular on mobile devices as soon as they were launched

In 1961, the famous Bell Labs developed the first electret (ECM) microphone, which uses the change in the size of the capacitor on the diaphragm caused by sound to convert sound into an electrical signal.

After that, electret microphones became popular nationwide for more than 40 years, until 2003, when the first commercial MEMS microphone product came out on the market - the SiSonic microphone from Knowles.

At this time, mobile phones gradually became popular in the market, and they became thinner and lighter. Traditional electret microphones could not meet the requirements of mobile devices for light, thin and small microphones. The advent of MEMS microphones won the favor of mobile phone manufacturers.

In 2003, Knowles Electronics took the lead in shipping MEMS microphones to Kyocera of Japan for use in mobile phones. In the same year, Motorola used Knowles' MEMS microphones in its ultra-thin mobile phone RAZR. Knowles Electronics has sold more than 10 billion SiSonic microphones.

According to Yole Developpement statistics, the shipment volume of MEMS microphones has gradually exceeded that of ECM since 2015, when MEMS microphones were commercialized for only 12 years. Since then, the shipment volume of MEMS microphones has increased by double digits year after year.

MEMS inertial sensors: making inertial measurement of mobile devices possible

Did you know? The world's first truly large-scale commercialized MEMS sensor is the accelerometer, which was invented by ADI in the United States in 1991. The sensor is based on the principle of capacitive sensing, and the output signal of the sensor can be used to measure acceleration or tilt.

This MEMS accelerometer is mainly used in automobile airbags. Previously, traditional sensors for automobile airbags cost $20 each, while ADI's MEMS accelerometers cost about $5 each, which reduced the cost of airbag electronics by about 75%.

Since then, MEMS inertial sensors have quickly become popular, replacing traditional inertial sensors in many fields such as automobiles, and creating more application scenarios - such as mobile phones, smart watches, TWS headphones and other mobile devices. Measurement becomes possible.

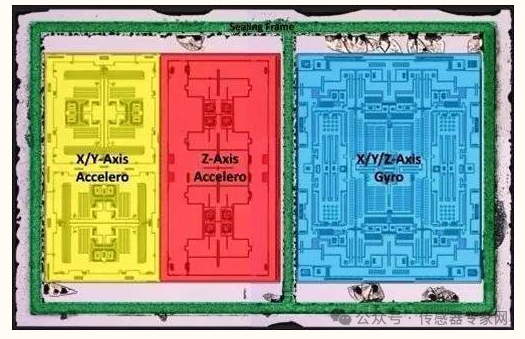

MEMS inertial sensors mainly include MEMS gyroscopes, MEMS accelerometers, and MEMS-IMUs (inertial measurement units).

Gyroscopes sense the rotation state of an object by measuring angular velocity. Since Sperry invented the world's first practical gyroscope, gyroscope technology has gone through nearly a hundred years of development and is the core of inertial technology.

In 1989, the first micromechanical gyroscope using MEMS technology was introduced, with a drift rate of 10 degrees per hour. Compared with other gyroscopes, MEMS gyroscopes are lower in cost, smaller in size, more reliable, and easier to mass produce, making it possible to use gyroscopes on mobile devices.

In smart phones, gyroscopes work with GPS, geomagnetic sensors, etc. to achieve precise positioning and navigation functions. At the same time, the gravity sensing characteristics in games are more powerful and intuitive, and the gaming effect will be greatly improved. This function allows the phone to continue to navigate for users with the acceleration direction and size sensed by the gyroscope when entering a tunnel and losing the GPS signal. The three-axis gyroscope will be combined with the original distance sensor, light sensor, and direction sensor of the iPhone to bring the human-computer interaction function of the iPhone 4 to a new level.

MEMS-IMU (Inertial Measurement Unit) consists of MEMS accelerometers and MEMS gyroscopes, and has the ability to measure acceleration and angular velocity. It has a wide range of applications. The first micro-electromechanical inertial measurement unit was developed by the Draper Laboratory in the United States in 1994.

▲Inside the nine-axis inertial measurement unit of InvenSense (TDK): gyroscope (right) and accelerometer (left)

The development of MEMS IMU was mainly driven by military demand in the early stage, and then gradually extended to civilian use. It has now been widely used in consumer electronics, automobiles, industrial automation and other fields.

At present, with the rapid development of MEMS IMU technology and the decline in cost, MEMS IMU has a trend of gradually replacing independent MEMS accelerometers and MEMS gyroscopes.

MEMS pressure sensor: driving pressure detection to miniaturization

Pressure is the second largest measurement value among various physical quantities. As mentioned above, the world's first MEMS sensor is a silicon micro pressure sensor, which was introduced in 1962 and developed by Honeywell.

At present, Honeywell's pressure sensor products cover a variety of scenarios. Its various pressure sensors such as absolute pressure, gauge pressure, true gauge pressure, and small pressure sensors can meet the most stringent test and measurement specifications in the world's harshest environments, including general industrial process requirements and pressure sensors dedicated to hazardous areas.

Compared with traditional pressure sensors, MEMS pressure sensors have the advantages of no mechanical fatigue or aging, stable output signal, high sensitivity, small size, and suitable for mass production (cost advantage). With the development of mobile devices and automobiles, MEMS pressure sensors are becoming more and more popular.

In the field of medical health, pressure sensors are widely used in equipment such as blood pressure monitors, ventilators, and monitors to provide doctors with accurate physiological parameter data. In addition, with the rise of wearable devices, pressure sensors are also used in smart bracelets, smart watches and other devices to realize functions such as heart rate monitoring and sleep analysis.

▲MEMS pressure sensor application, source: Yole

A significant advantage of MEMS pressure sensors is that they can be very small, which has promoted the application of pressure sensors in innovative fields such as miniaturized mobile devices and medical treatment.

For example, Tyco Electronics previously launched the industry's first micro-invasive MEMS pressure sensor, which is as thin as a hair, promoting the application of pressure sensing in the field of medical equipment. In the future, the IntraSense series of sensors can be used on minimally invasive medical devices such as diagnostic catheters, treatment catheters, disposable endoscopes, biopsy needles, and ablation devices. Doctors do not need to rely solely on experience to perform related minimally invasive surgeries, but can judge based on accurate pressure values, which will bring about a huge change in the digitization of the existing medical industry.

MEMS DLP chip: the pinnacle of traditional projection equipment, opening up the era of digital laser projection

DLP projection technology is an epoch-making revolution in the display field, just like the huge impact of CD in the audio field, DLP has opened a new page for video projection display.

Dr. Larry J. Hornbeck, the inventor of the digital micromirror device (DMD, or DLP chip) of Texas Instruments, won the 2014 Academy of Motion Picture Arts and Sciences Award for Science and Technology, and was recognized for his outstanding contribution to transforming the century-old film industry into digital film technology! This shows the important influence of MEMS DLP chip technology on the imaging industry.

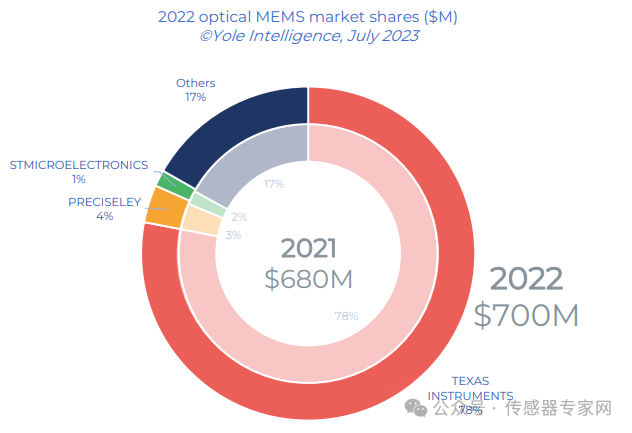

The core device of DLP (Digital Light Processing) chip is DMD (Digital Micromirror Device), which is an important category of optical MEMS.

In 1977, the research and development of DLP chip was officially launched at the Texas Instruments Central Research Laboratory. At that time, Hornbeck first used "deformable mirror" to control light in an analog way, but the analog technology used was always difficult to meet the expected requirements. It was not until 1987 that he made a breakthrough in technology and invented DMD (i.e. DLP chip) based on MEMS technology that this situation changed.

Since then, DLP technology projectors have long occupied more than 60% of the market share and are the mainstream projection technology solution in the market. This situation has not changed until the past two years.

At present, most DLP chip technologies are exclusively patented by Texas Instruments. According to Yole's data, with the revenue from DLP chips, Texas Instruments occupies nearly 80% of the global optical MEMS market.

▲Global optical MEMS market share in 2022, source: Yole

MEMS inkjet head: three-quarters of the printing world, can also print DNA structures

In inkjet printers, MEMS inkjet print heads are the most core components, and their function is to squeeze out ink. Some use piezoelectric film vibration to squeeze out ink, and some use heated bubbles to expand and squeeze out the ink in the cavity.

Interestingly, these two MEMS inkjet technologies have formed two major camps of printers, with micro-piezoelectric printing technology represented by Epson and Brother, and manufacturers such as HP and Canon that use thermal bubble printing technology, competing with each other.

At present, inkjet printers, laser printers and dot matrix printers share the market and are one of the mainstream printing technology solutions.

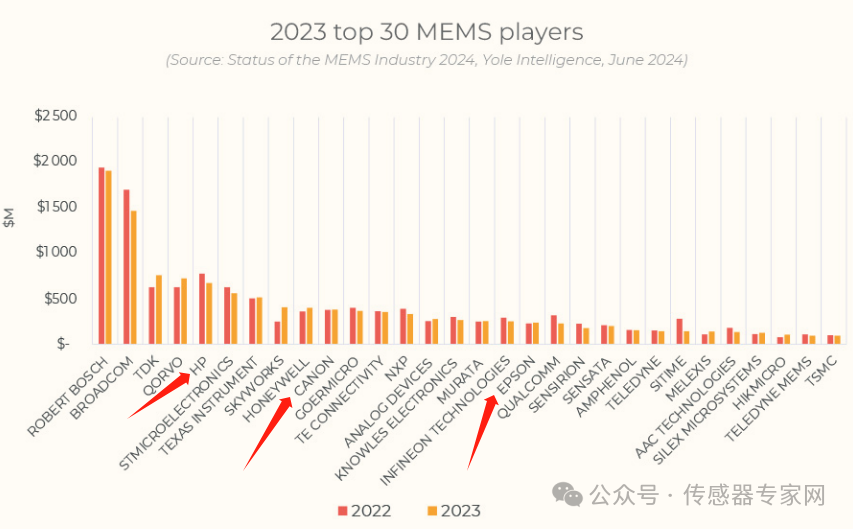

Thanks to the shipment volume of MEMS inkjet print heads, printer manufacturers such as HP, Epson, and Canon have long been included in the global TOP 30 list of MEMS device shipments.

▲Source: Yole

In addition to printing text and photos, MEMS inkjet technology is also used in the construction of DAN arrays in the field of medical and biological research, replacing traditional ink with synthetic reagents.

In DNA synthesis technology, inkjet printing synthesis technology has become the focus of most attention due to its high throughput, high efficiency and low cost, and has greatly promoted the development of DNA synthesis. The number of related patents has also increased significantly in recent years.

Conclusion

MEMS technology is one of the most revolutionary high-tech technologies in the 21st century. From this article, we can see the disruptive applications of MEMS devices such as MEMS microphones, inertial sensors, pressure sensors, DLP chips, and inkjet heads in various fields. The emergence of MEMS devices has greatly promoted and expanded the application boundaries of traditional devices.

In addition to the MEMS sensors and actuators mentioned in the article, MEMS filters, MEMS thermopiles, etc. are also widely used. At the same time, new MEMS technologies, such as MEMS speakers and MEMS clocks, are also showing a vigorous development momentum and are expected to subvert related tracks in the future.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

Join us at August 28–30 in Shenzhen, and let’s shape the future of technology together!

To register IOTE 2024 Shenzhen station:

https://eng.iotexpo.com.cn/sz/Visitors.html?lang=EN&source=YJ1