ITEC, an independent subsidiary under Nexperia Anshi Semiconductor, equipped with advanced facilities, automation expertise, and over 30 years of semiconductor manufacturing experience, is dedicated to becoming a key partner in equipment and automation for its clients.

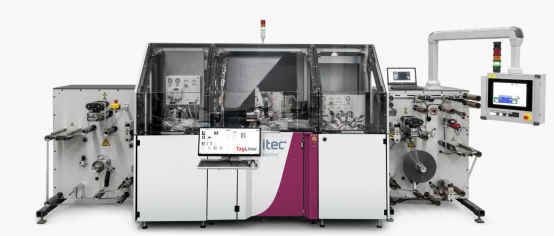

ITEC has successfully translated its high-speed encapsulation chip technology into a groundbreaking solution for RFID (Radio-Frequency Identification) back-end packaging. The latest model, ADAT3 XF Tagliner, boasts an impressive encapsulation speed of 48,000 units per hour, positioning itself as an industry leader in the RFID sector.

Speed is not the sole advantage of this device; the ADAT3 XF Tagliner introduces several features that surpass industry standards and deserve attention.

1. Significant Reduction in Curing Time and Material Loss

The ADAT3 XF Tagliner employs a high-precision adhesive curing system with only two thermal electrodes, reducing moving parts to enhance reliability and maintainability. With a curing time of just 65 milliseconds, a magnitude lower than traditional RFID die-bonding machines, it significantly improves operational efficiency.

2. Reduced Footprint and Lower Total Cost of Ownership (TCOO)

Total Cost of Ownership is a crucial metric in the semiconductor industry, reflecting the sum of asset acquisition costs and costs incurred throughout its entire service life. The ADAT3 XF Tagliner addresses the need for smaller devices to improve space utilization, thereby reducing the costs associated with factory floor space. The machine’s compact dimensions, measuring only 5397 x 1500 x 2617 mm, make it one of the smaller products in its category, enhancing space efficiency in RFID production.

3. Insensitivity to Bonding Pad Distance

Unlike existing RFID back-end packaging devices where an increase in bonding pad distance results in a sharp decline in production speed, the ADAT3 XF Tagliner maintains a production speed of 48,000 units per hour regardless of the product’s bonding pad distance within 2 inches. This insensitivity is achieved through process optimization by ITEC.

4. Compatibility with Various Transparent and Non-transparent Tape Materials

In contrast to traditional RFID die-bonding devices limited to transparent materials, the ADAT3 XF Tagliner has a competitive edge. Its top-down light source system ensures accurate positioning and reading of non-transparent materials, meeting diverse production needs.

5. Improved Wafer Exchange Process

The ADAT3 XF Tagliner incorporates standard features required by the semiconductor industry, facilitating automatic wafer exchange for 8-inch and 12-inch wafers. It seamlessly integrates with the production requirements of RFID tag back-end packaging. The automated wafer exchange process takes less than 5 minutes, reducing the labor involved in wafer replacement.

6. Comprehensive Quality Control through Multiple High-Speed Cameras

Considering the stringent precision requirements for semiconductor products used in applications like automotive and computers, ITEC has integrated numerous high-speed cameras into its design. During production, these cameras rapidly capture encapsulation position information, providing feedback to the platform to assist in automatic adjustments of chip packaging angles and distances on the Inlay.

7. Process Enhancement through High-Speed Heat Press

Unlike traditional back-end packaging devices with a step-by-step heat press and winding process, the ADAT3 XF Tagliner utilizes high-speed heat pressing for rapid and continuous winding. This non-stop encapsulation method accelerates overall production speed.

ITEC’s ADAT3 XF Tagliner emerges as a pioneering solution in the RFID industry, combining cutting-edge technology with enhanced efficiency and cost-effectiveness.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

Join us next year in Shanghai, and let’s shape the future of technology together!

To register IOTE 2024 Shanghai station:

https://eng.iotexpo.com.cn/sh/Visitors.html?lang=EN&source=YJ1